Fragile items are quite different from ordinary products, and more care should be given to during handling and transportation. Under normal circumstances, fragile goods should be protected both inside and outside before shipping.

How to packing fragile items?

External packaging

External packaging, usually cartons, is the protective packaging that goes around outside of the fragile items. This is the most commonly used and necessary way to avoid damage to the fragile items in transit. The outer packaging cartons should have strong compression resistance and non-deformation ability, and can effectively protect fragile items from damage during normal storage, stacking, and transportation.

However, outer packaging cartons are from enough to protect fragile items. Various happenings such as bumps and shaking will inevitably be encountered in transit(You can't expect porters or warehouse worker to treat your fragile goods with special care amid mountains of boxes).

Inner Cushioning

Therefore, internal cushioning for fragile products is extremely necessary. Simply put, the function of the inner packaging is to isolate the fragile product from direct contact with the packaging carton, and fix it to prevent it from shaking in the box. Therefore, many people choose cushioning filling packaging materials as protective packaging materials for fragile products. Cushioning packaging materials can return to the original shape (or approximately) in a short time after being subjected to external impact, This can further provide a buffering effect and protect the fragile items from damage by shaking, bumps, vibrations, etc.

What's the best packing material for fragile items?

Features an excellent internal cushioning packaging material needs to have:

1. Sufficient cushioning. Needless to say, as it's why it's needed there.

2. Low price. The packing material must be cheap, because the amount used for filling protection must not be small. If the material is too expensive, it will be for the merchants There is no benefit at all.

3. Light weight. Many express logistics companies often calculate the cost based on the weight of the goods when transporting the goods. If the buffer filling protection material is too heavy, it will increase the transportation cost, and the gain is not worth the loss.

4. Easy to store. Packaging materials like this kind of cushioning filling must be easy to store and convenient to use, so that the product cannot be packaged and delayed for delivery due to one or other reasons.

5. Non-toxic. Cushioning filling packaging materials are generally used in conjunction with packaging cartons. From the completion of packaging to unpacking again, the transported products are basically in a closed state with slow air flow. Such packaging materials produce certain harmful substances, which will cause very serious consequences.

What's exactly the best packing material for fragile items?

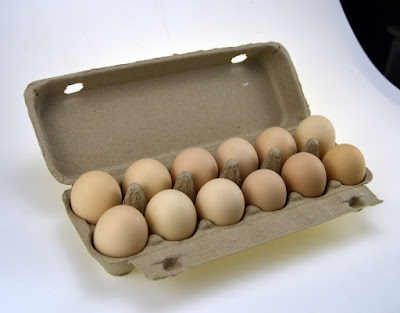

Things like EPE, foam, inflatable bags and packing peanuts are all great cushioning materials. But no single packing material seems to be the right answer, as it largely depends on what fragile items it is to pack. For example, to ship fresh eggs, paper mache eggs cartons/holders (as shown below) are the best packing material.

No comments:

Post a Comment